Protective Coatings

Protective coatings are applied to surfaces to prevent corrosion, wear, and other forms of degradation. Common types include epoxy, polyurethane, acrylic, and ceramic coatings, each offering specific benefits like chemical resistance, UV protection, or fire resistance. Other categories include galvanizing, powder coating, and various specialized coatings like anti-graffiti or hygienic coatings.

1. Epoxy Coatings

Excellent adhesion and chemical resistance; used on floors and heavy machinery.

2. Polyurethane Coatings

UV resistance and flexibility; suitable for exterior and metal surfaces.

3. Zinc Coatings (Galvanization)

Zinc acts as a sacrificial layer to protect steel from corrosion.

4. Ceramic Coatings

High-temperature and chemical resistance for extreme-heat applications.

5. Acrylic Coatings

Versatile and easy to apply; suited to less demanding environments.

6. Alkyd Coatings

Usable in various climatic conditions; durable film.

7. Silicone Coatings

Weather-resistant with high-temperature stability.

8. Intumescent Coatings

Fire-protection; expand when heated to form a protective barrier.

9. Metallic Coatings

Electroplating or thermal spray to deposit protective metal layers.

10. Organic Coatings

Polymer/resin-based films providing protective layers.

11. Powder Coatings

Dry powder applied and melted into a smooth, durable finish.

12. Cathodic Protection

Sacrificial metal or impressed current used to prevent corrosion.

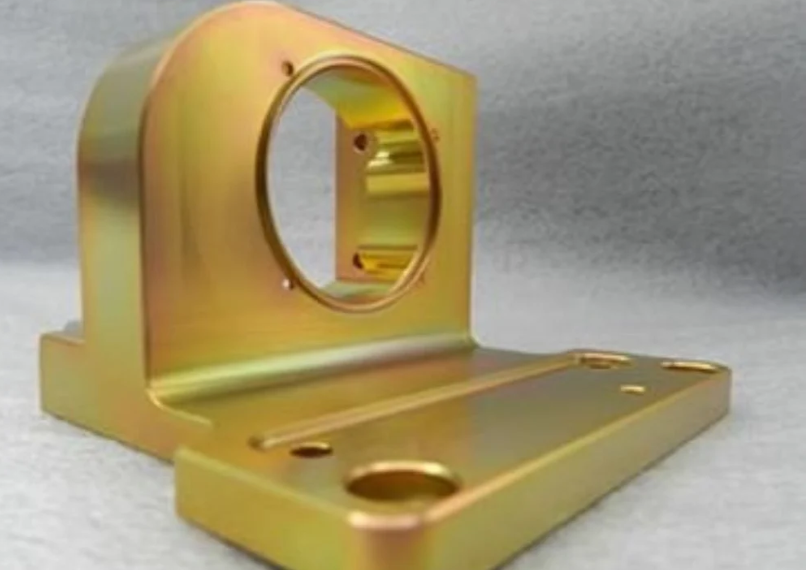

13. Chromate Conversion Coating

Chemical treatment forming a corrosion-resistant film.

14. Phosphating

Phosphate layer enhances paint adhesion and corrosion resistance.

15. Anodizing

Electrochemical oxide layer, typically on aluminium.

16. Paints and Primers

Various paint systems for corrosion protection and aesthetics.